System solutions created by your connection specialist

holistic concepts from a single sourceManual workstations

customized, modern and ergonomic

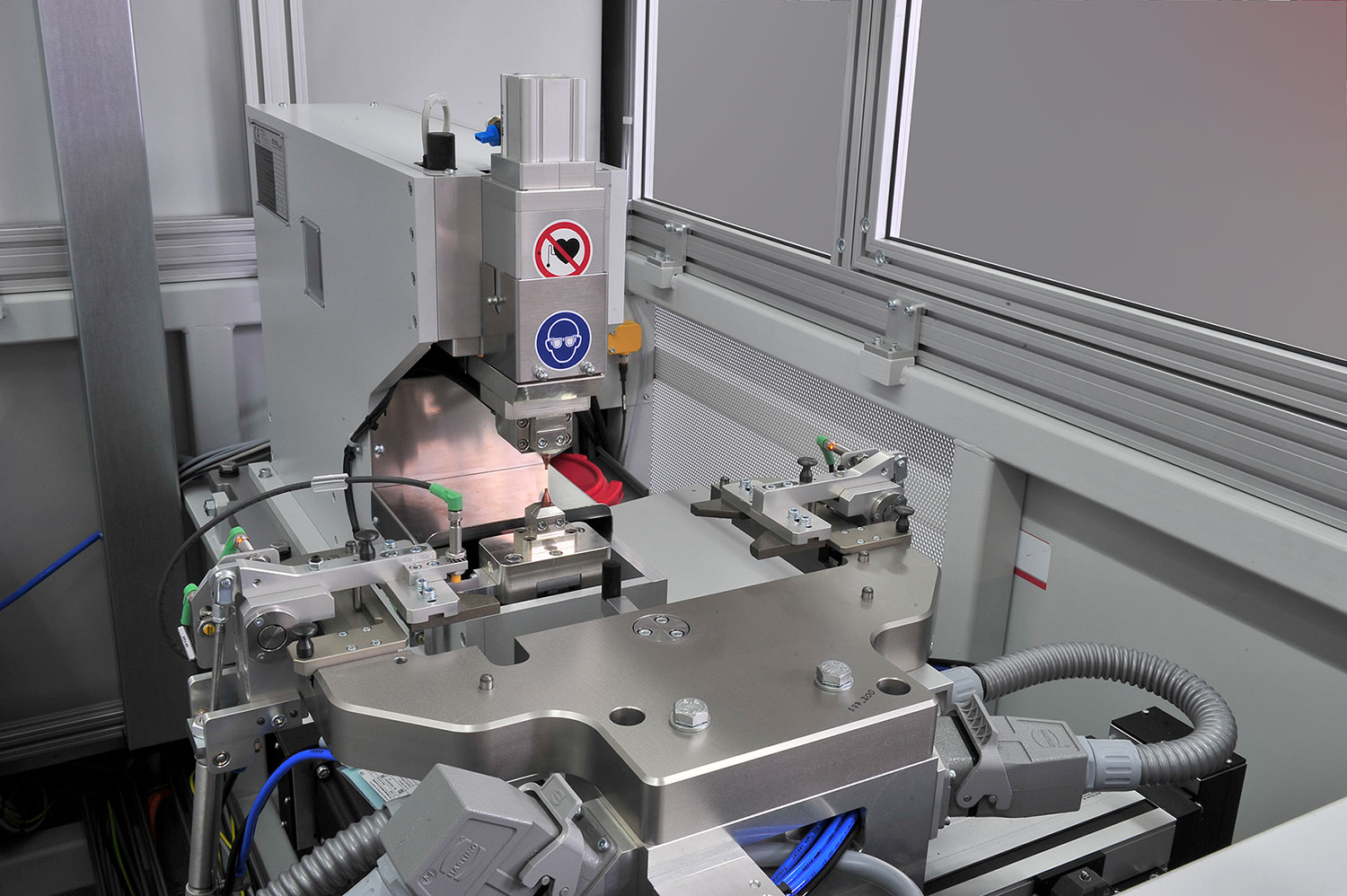

Where automatic machines cannot be used due to quantities or production strategies, our manual workstations ensure process reliability with high efficiency and quality.

Adaptable manual production

Automatizaton is not useful in all cases. Manual workstations that combine human work with high process reliability are particularly recommended for small batch sizes, a large variety of types or a large number of variants. They are also indispensable in high-quality production. Even complex assembly processes may require steps in which humans cannot be replaced (without considerable technical effort). The same applies to final and intermediate inspections, which are difficult to implement without the expert knowledge and sensory skills of humans.

Customized manual workstations

We engineer manual workstations that increase efficiency and enable you to meet the highest quality standards. You can choose between:

- standard solutions with or without table top,

- sequencers for splicing in pre-assembly or as an inline system for the cable board and

- customized machines for all technologies used to weld connections in non-ferrous metals.

Even if you have to meet special requirements and are looking for a tailor-made concept, you have come to the right place. As an expert for customized solutions in this field, we promise we will be able to find an appropriate solution for you.

Flexible concepts and individual solutions

Whether you come from the automotive industry, medical technology, the electrical and solar industry or electrical engineering – we can provide you with an all-round solution that exactly meets your needs. In addition to our manual workstations, we also offer high-quality semi-automatic and fully automatic machines. You can rely on our experience from over 50 years of process technology and the expertise of our highly qualified employees.

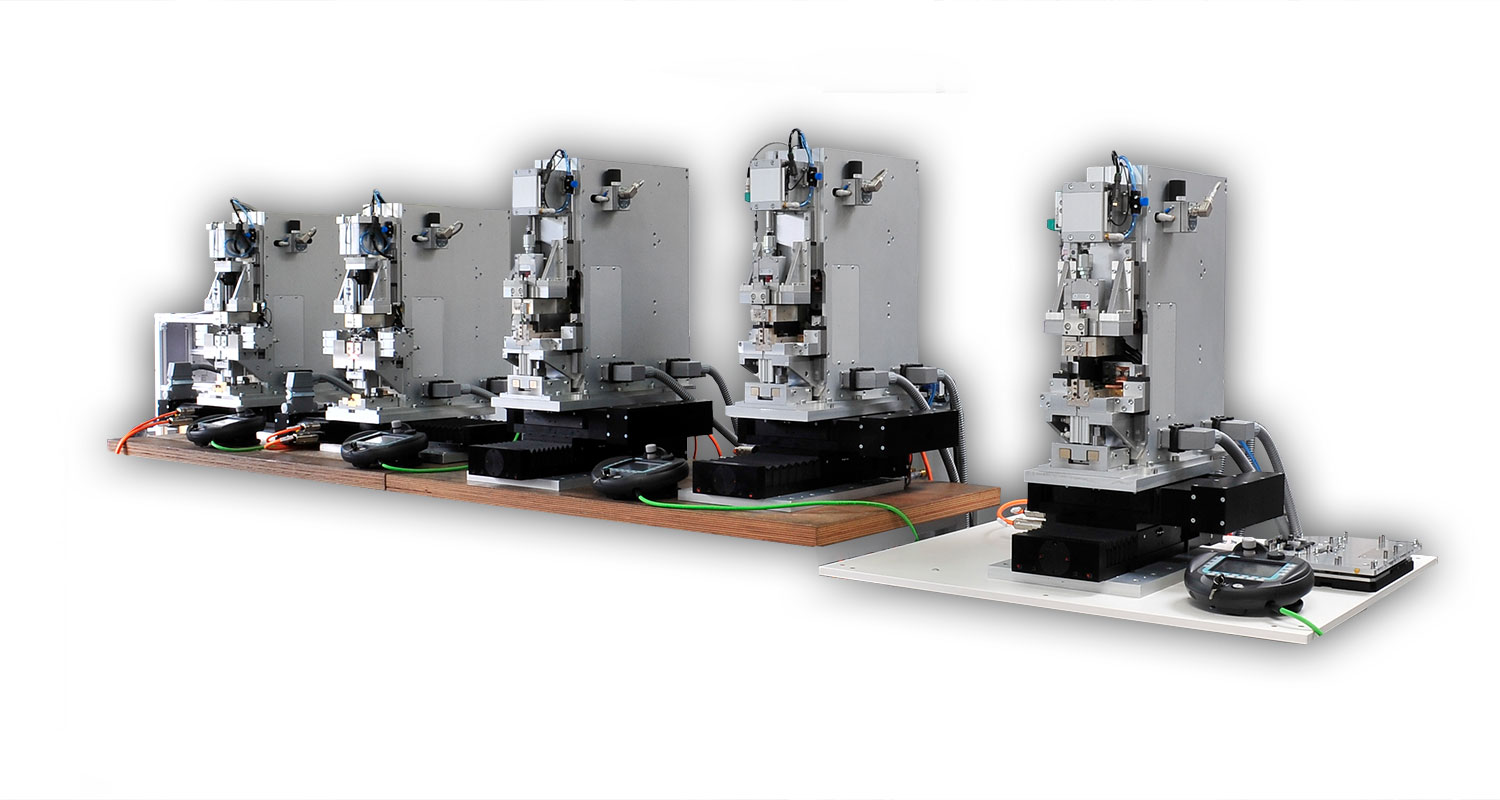

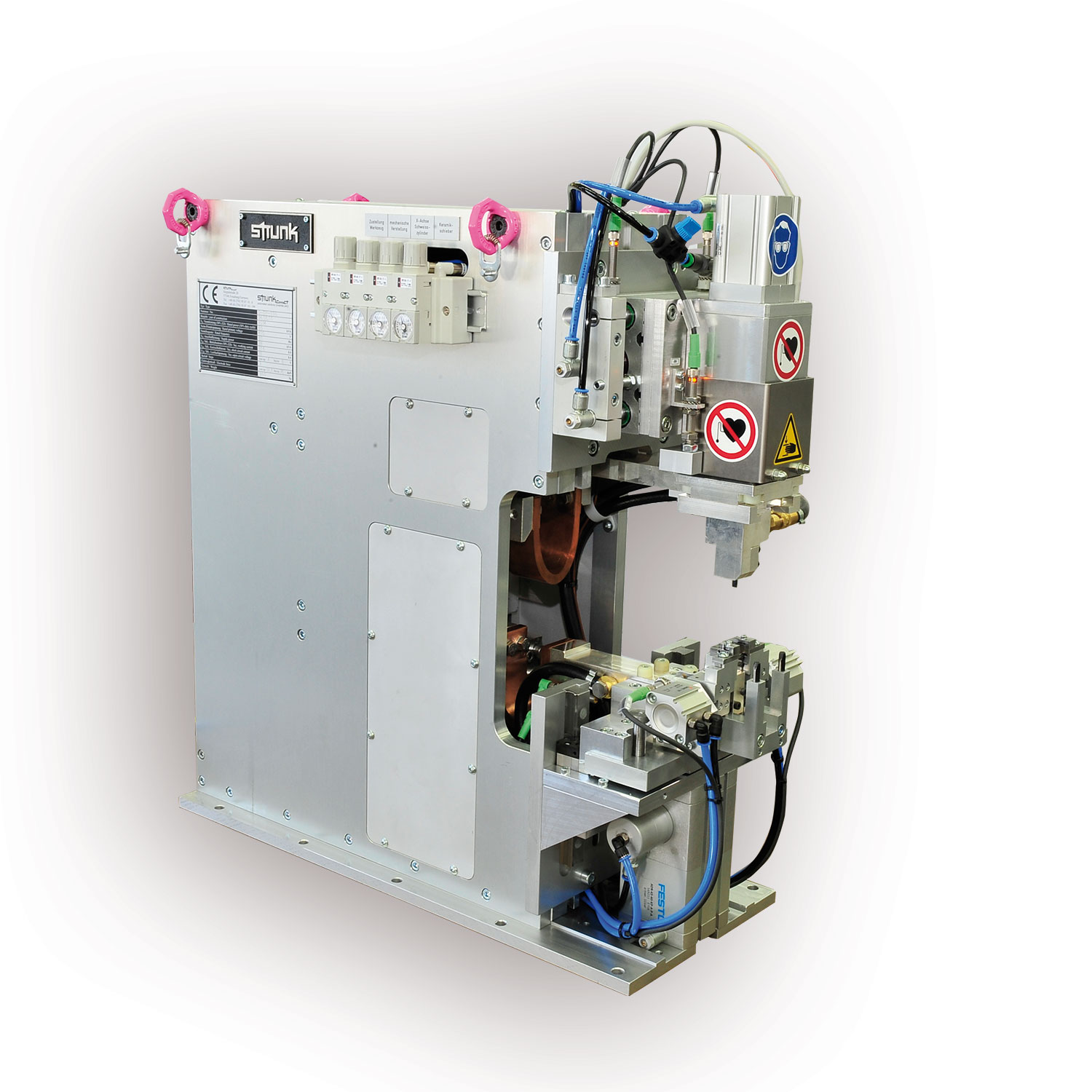

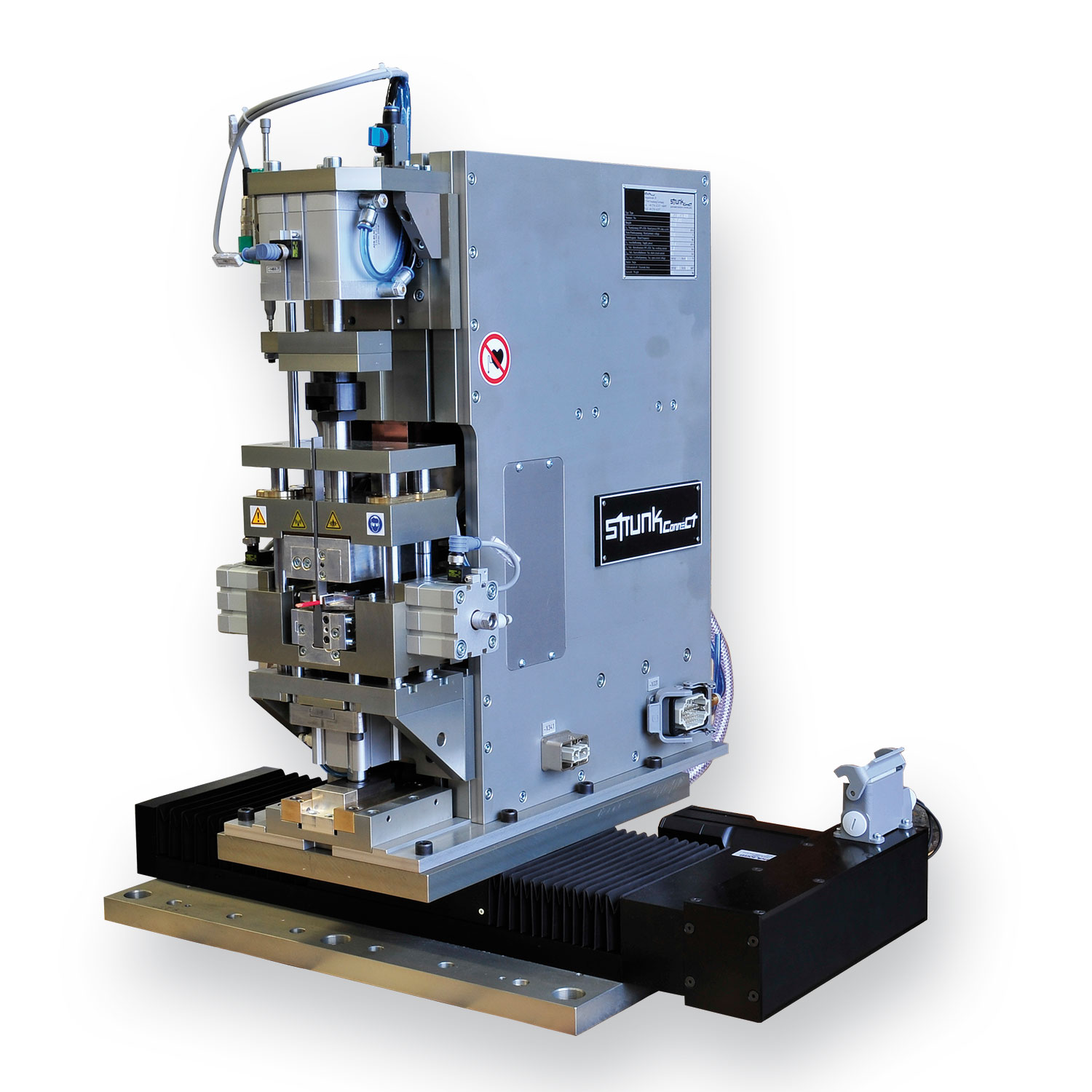

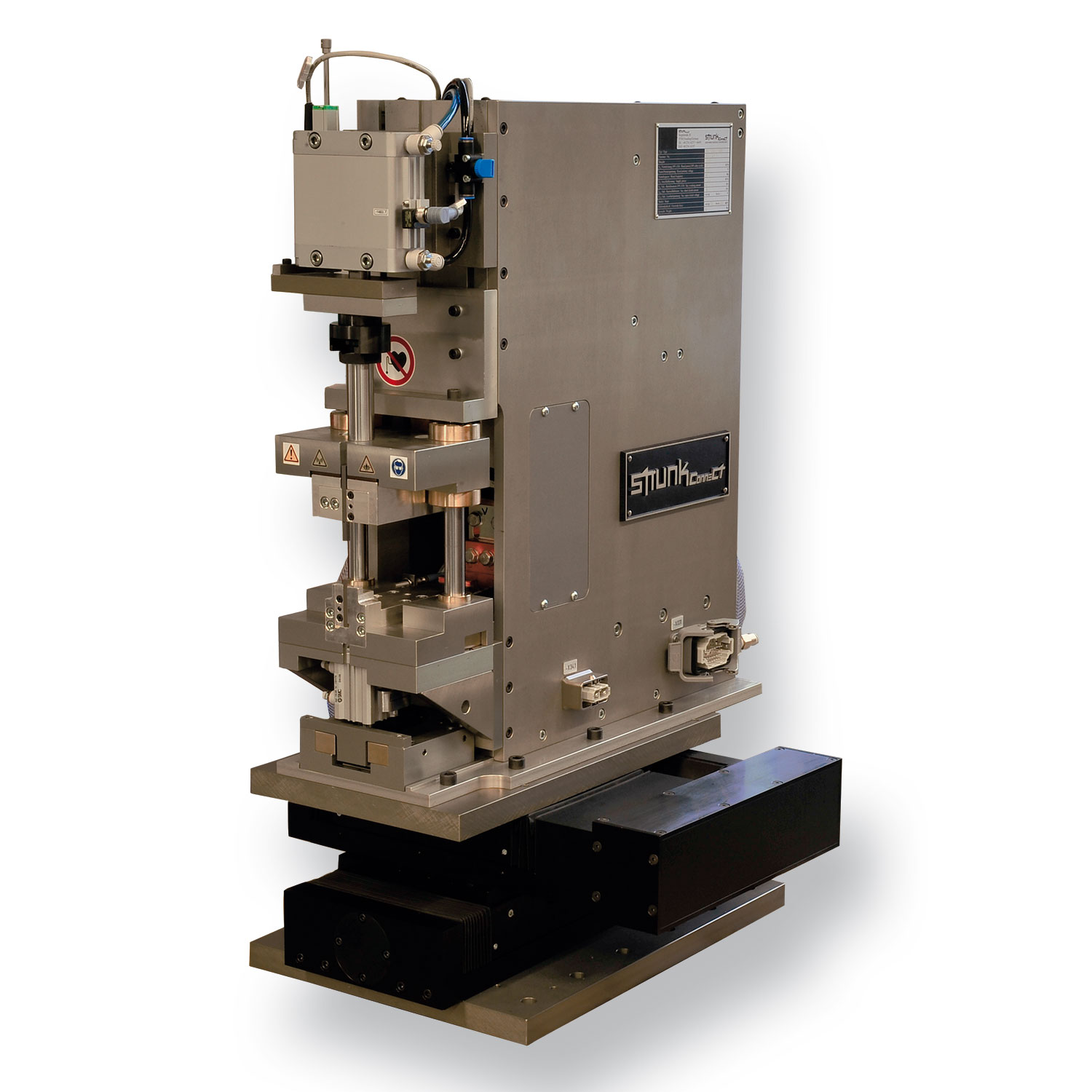

self-contained functional units

process responsibility for integration

Would you like to integrate our processes into the layout of your production line? Our proprietary connection process including development and process responsibility is a perfect fit for your line? Then our self-contained functional units with process responsibility for integration are the ideal solution.

Optimizing added value by modernizing and expanding

The pace of technological change is accelerating. In order to remain competitive, modern companies have to adapt to technological advances at ever shorter intervals. However, there is no need to invest in new production facilities or systems if the current equipment can be converted to new applications. This is what we offer for existing STRUNK systems. Furthermore, we offer extensions of existing production lines to increase their performance and efficiency. As a rule, very good results can be achieved with relatively little time and expense.

Modules as functional units with process responsibility

Consistently geared towards integration into your existing automation concept, our portfolio of closed functional units with process responsibility for integration includes the following systems:

- units for linear transfer systems with component feed,

- individual modules for wire processing centers as well as

- double-headed machines for wire processing centers or rotary indexing tables with component feed.

The latter enable simultaneous welding of two connections within a very short time frame. We manufacture welding units for terminals and compacting with connector conveyor, micro welding units and sequencers.

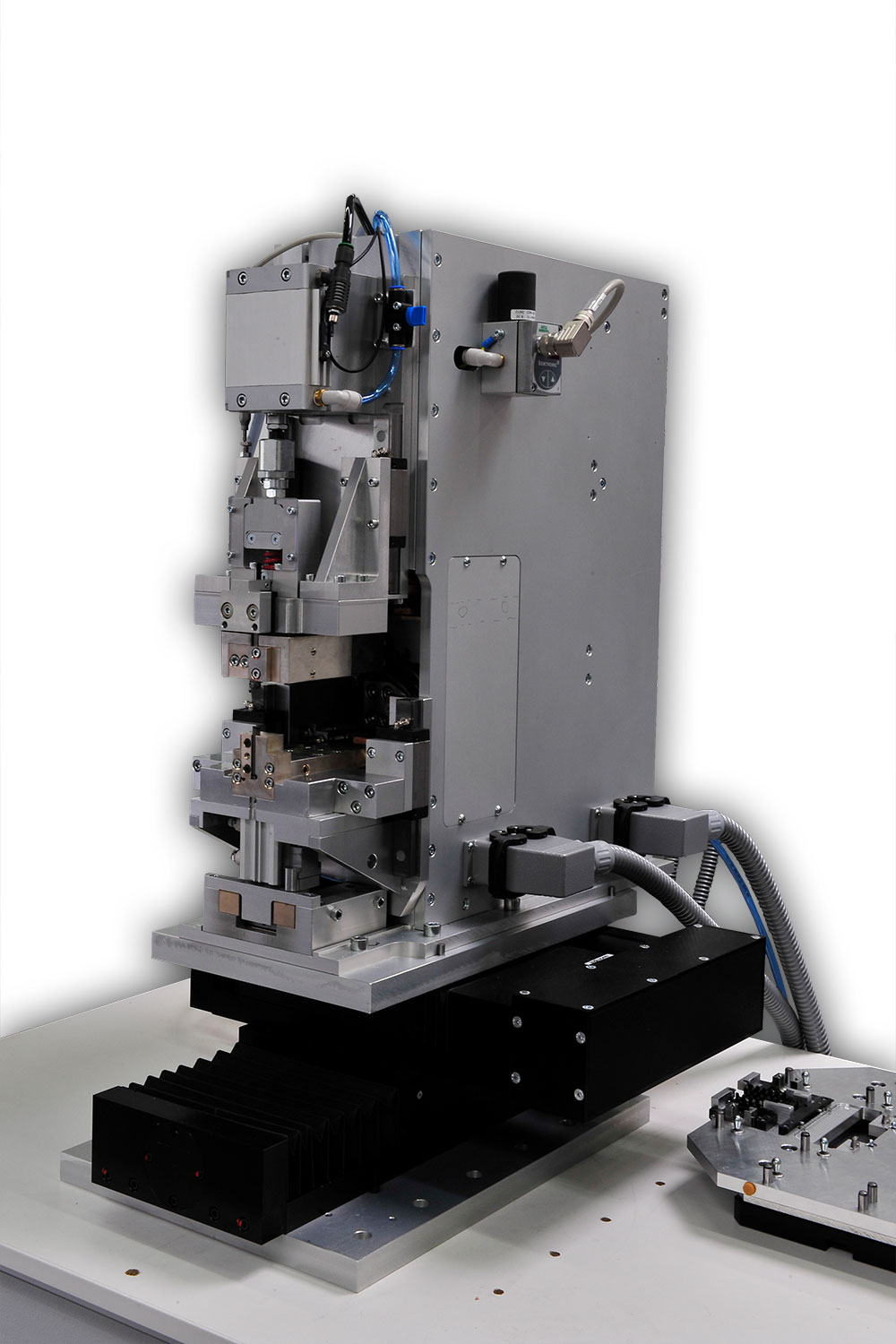

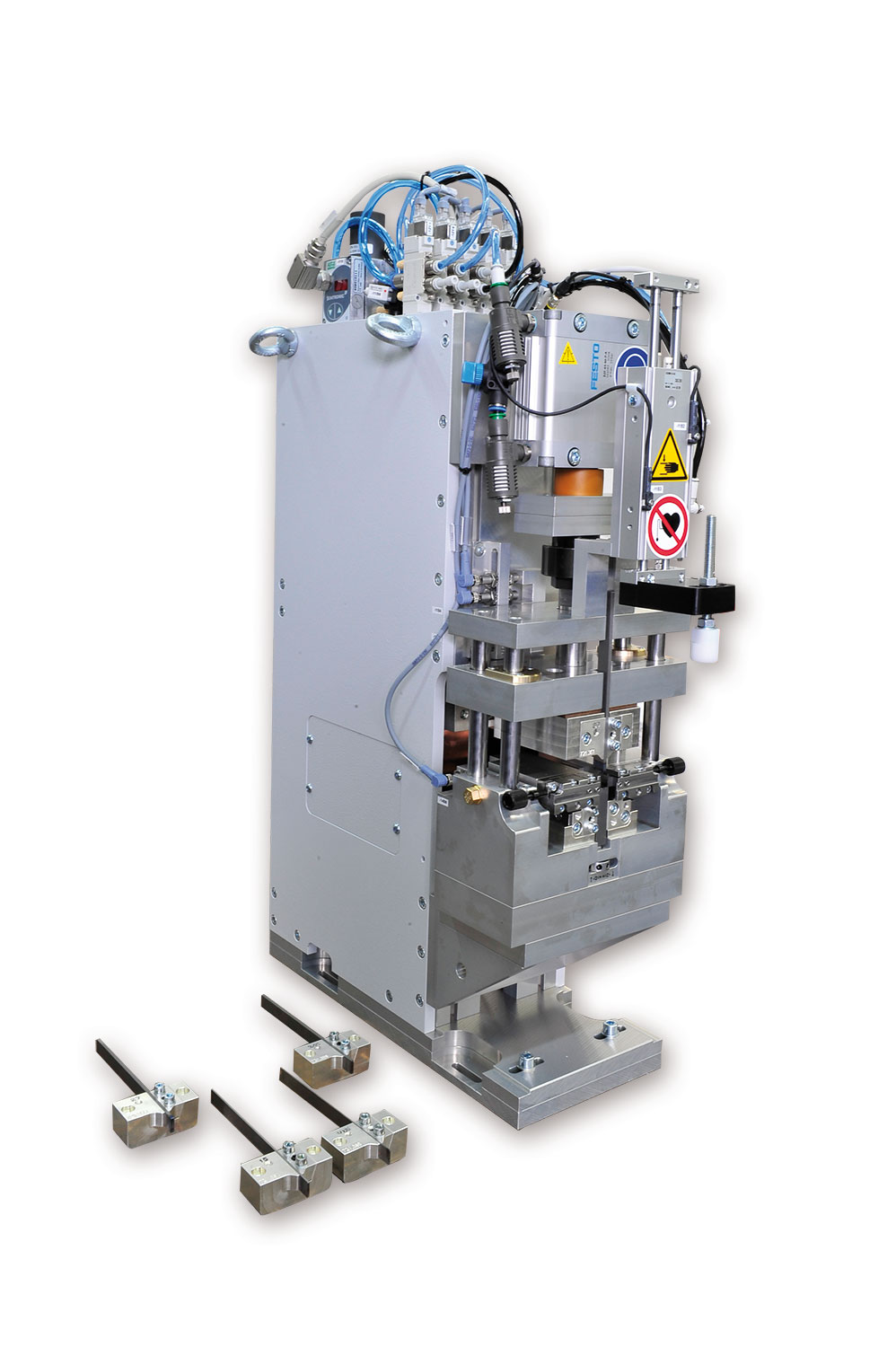

semi-automatic machines

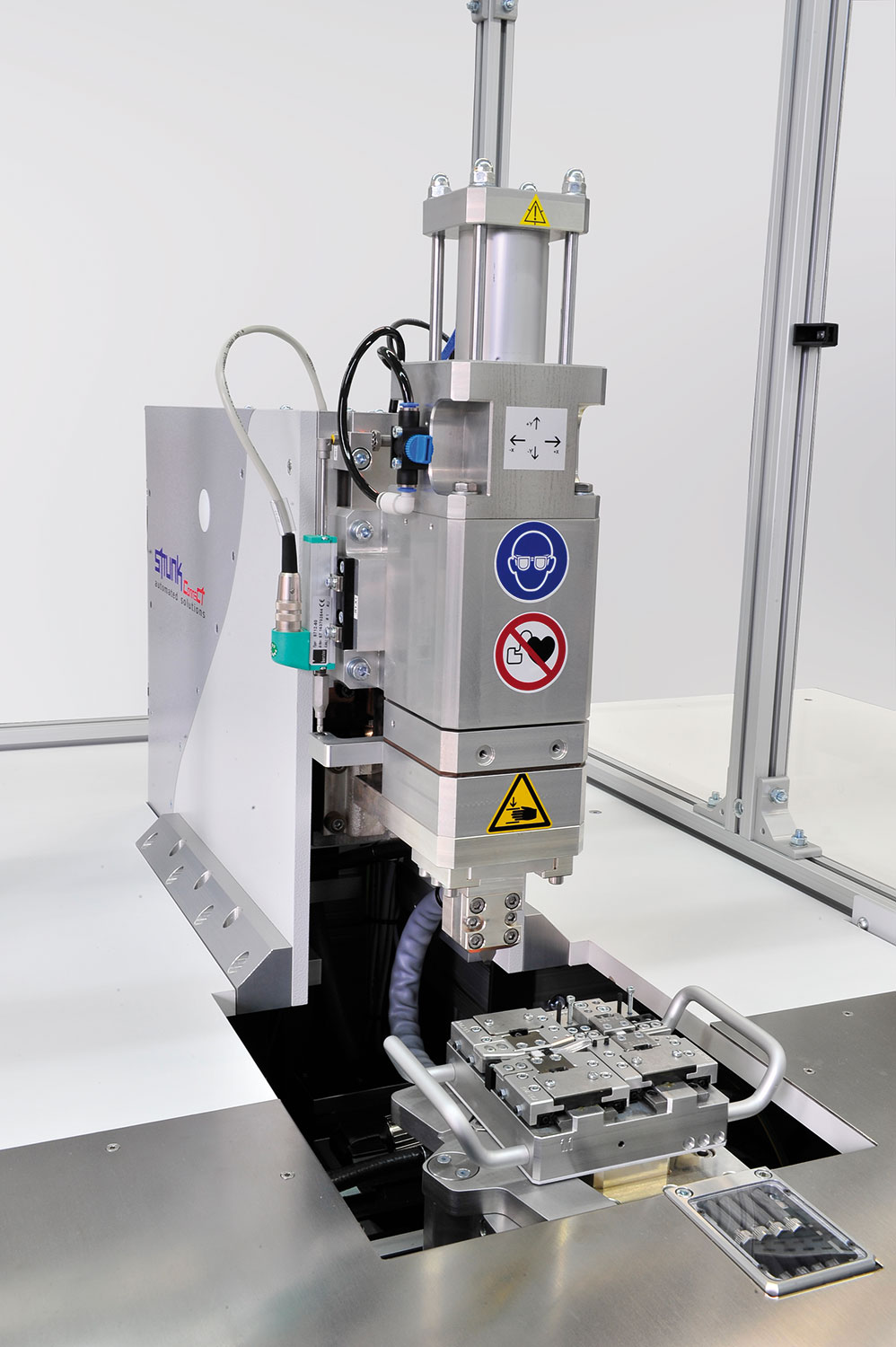

Increase production quantities cost-effectively

With our semi-automatic machines, we offer you solutions to increase the efficiency of your production processes.

Improve productivity and quality with partial automation

Time to market is a decisive competitive factor in many industries. Increasing volumes combined with shorter product cycles require automation solutions that increase efficiency and quality. Against this backdrop, hybrid assembly systems with a combination of manual workstations and fully automated production are becoming increasingly important.

Advantages of semi-automatic systems

Semi-automatic machines are used wherever the geometry of the components does not allow for automatic feeding. They are also a suitable alternative where the cost of full automation is not profitable due to low production volumes. Semi-automatic systems can also provide redundancies and backup solutions. Last but not least, they can be used to increase quantities by duplicating smaller units more quickly and cost-effectively.

Our powerful and highly precise semi-automatic machines

Our semi-automatic systems for just one worker lay the foundations for greater efficiency in your production processes. They are based on our in-depth understanding of the requirements of your industry, which we can implement in a targeted manner thanks to our many years of experience and high level of technical expertise.

The partial automation of processes using feeding technology with simultaneous interlinking via rotary table and transfer systems is also part of our range. Decouple feeding from processing time with our high-performance, high-precision semi-automatic machines. Thus, you can benefit from reduced processing time and improved repeatability.

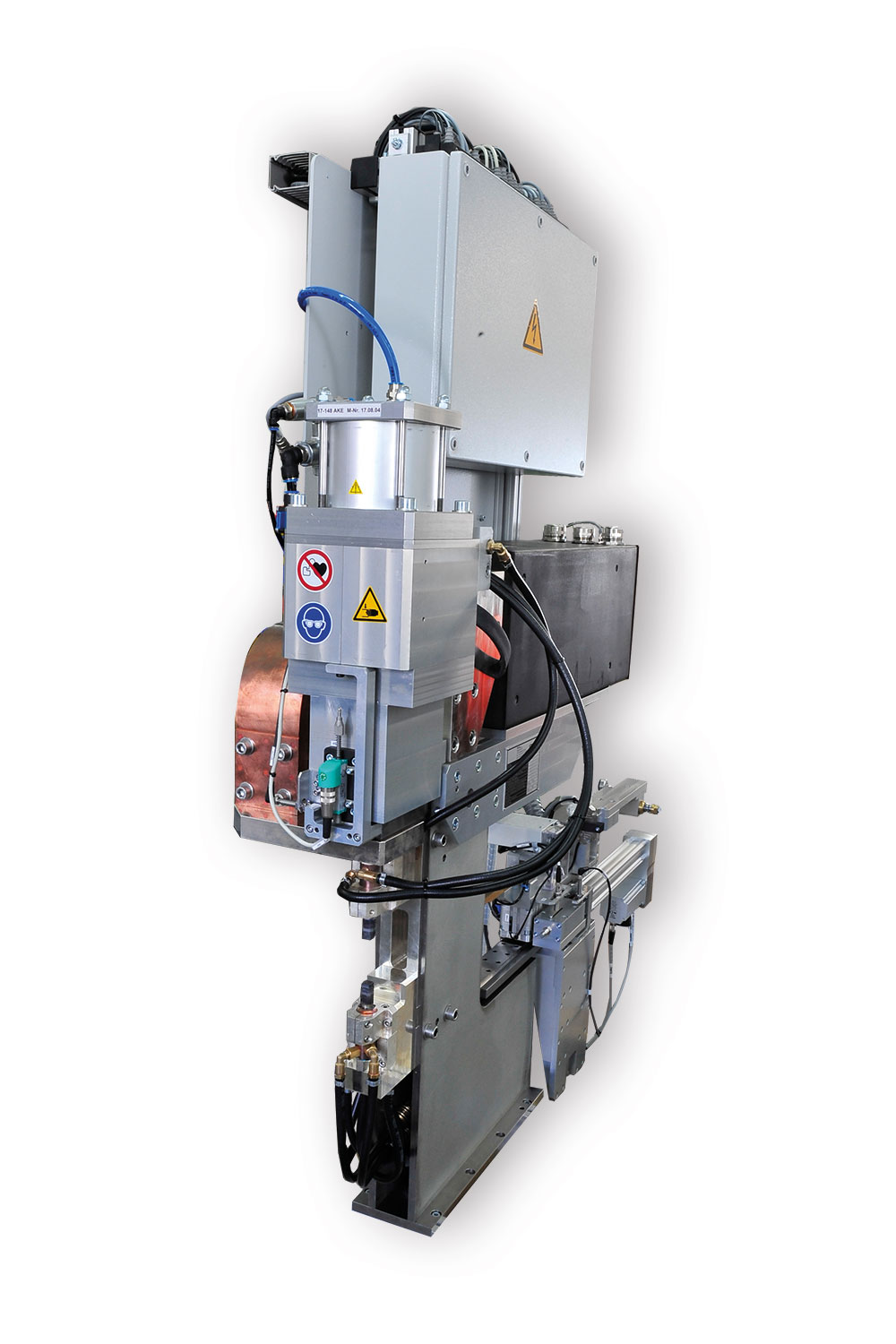

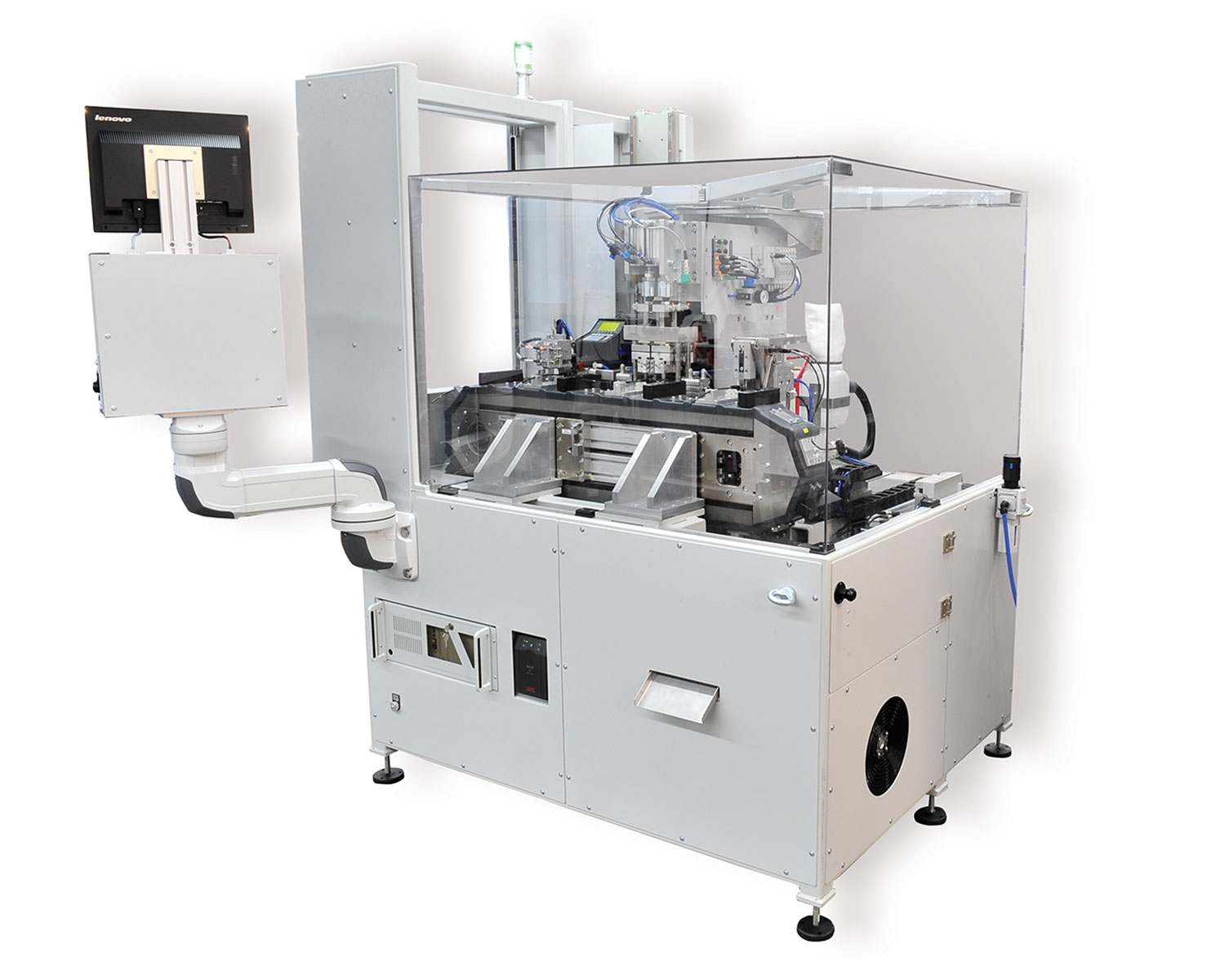

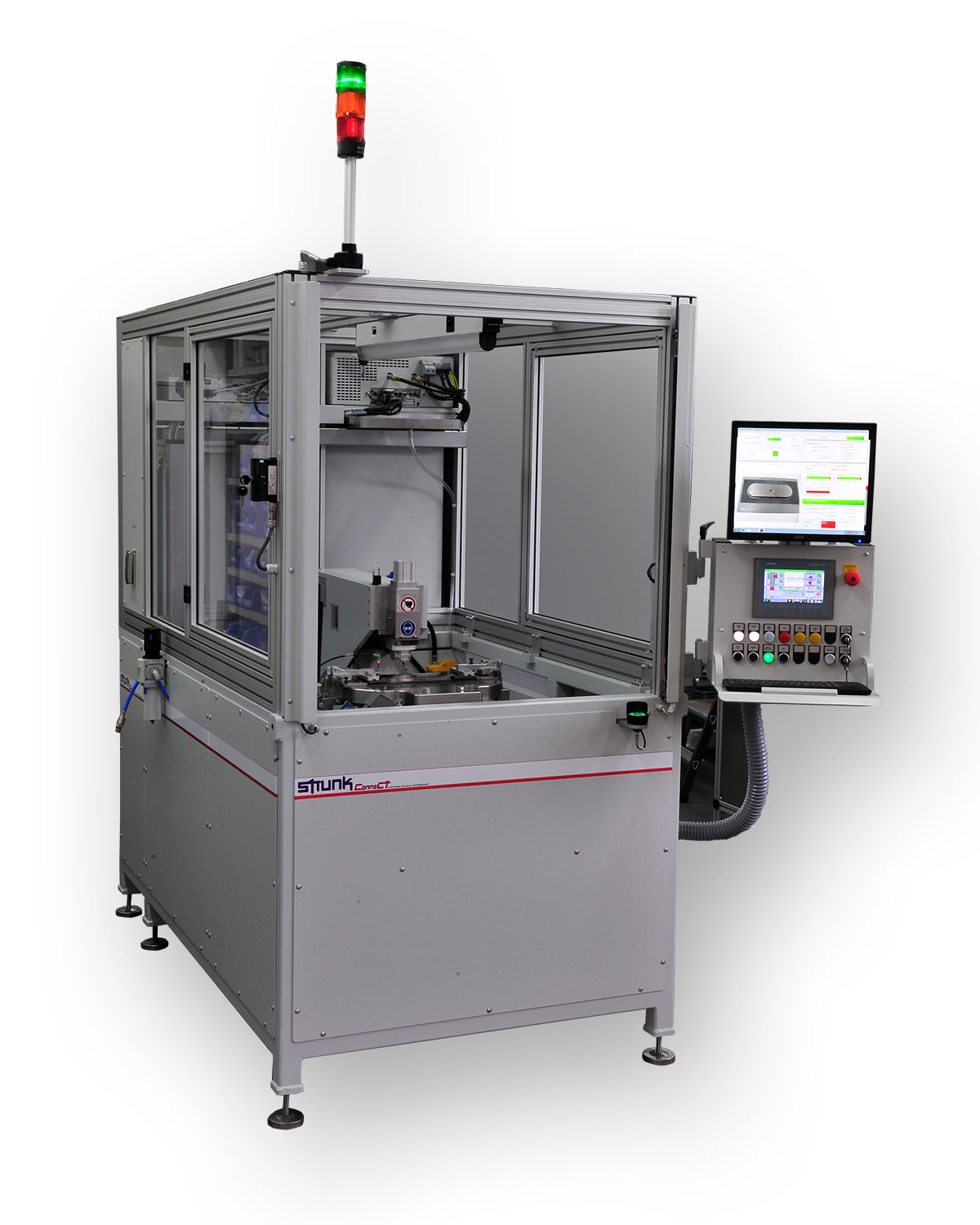

Fully automatic machines

customized solutions for your manufacturing processes

We support you with fully automated systems, including interlinking if required. Especially in the context of cables (flexible parts), our range also includes the industrialization of your products.

Produce more efficiently with high-quality automation solutions

The market demands ever-increasing efficiency while at the same time reducing costs. By automating your manufacturing processes, we can help you produce your desired quantities per year with consistent quality. This also includes traceability if used in conjunction with STRUNK MES (or comparable systems). Due to more complex architectures, the number of connections is currently increasing in many applications (especially in the EV/BEV sector). This means that production quantities can often only be achieved with fully automated systems.

Advantages of fully automated systems

The full automation of production processes has numerous advantages. For example, it allows for larger quantities to be processed while reducing errors at the same time. The use of fully automated machines eliminates the need for manual processes previously carried out by people. As a result, work steps and processes are accelerated, while the physical and mental strain on personnel is reduced. In our fully automated solutions, we combine even complex steps in one machine that could otherwise only be carried out by humans. Naturally, we make sure that the new systems are perfectly integrated into your existing process chain.

Our fully automated machines – complete solutions from a single source

As a turnkey partner for your production processes, we develop automation solutions for inline use. You can choose whether we develop your complete system as a general contractor or generate it with process responsibility for integration into your line. Our expertise covers the following specialist areas:

- resistance welding,

- handling of flexible parts (cables),

- feeding technology,

- ultrasonic laser and plastic welding,

- soldering and dispensing,

- assembly and testing technology as well as

- punching and bending operations.

Our fully automatic machines for production automation are designed specifically for your task. Benefit from our expertise and experience in the fully automated handling of customer processes using intelligent system solutions. They may include elements like longitudinal transfer, rotary indexing tables, tool carrier transfer and robotic cells.

Robotic cells

flexible applications for more efficient manufacturing processes

Robotic cells are helpful for automatization. They are versatile and work quickly and with precision while still maintaining flexibility. Robot technology can be used to perform placement tasks or to link our machines.

Our fully automatic, robot-assisted production systems

We often equip our fully automatic machines with robots to simplify handling more complex component geometries or a wide range of variants. These solutions are particularly suitable in combination with our rotary table systems in order to integrate the manufacturing processes for the production of assemblies. Ultimately, you can thus carry out the complete assembly.

Harness our know-how from more than 50 years of process technology and our expertise from a wide range of application projects. Let us help you gain an advantage over your competitors.

machines and welding current control

comprehensive functionality for a wide range of applications

Without adequate controls, neither our processes nor our automation solutions can function. For this reason, we also offer machine and welding current controls that are specifically adapted to your application.

No automation without controls

Partially and fully automated production offers numerous advantages over conventional workstations. However, in order to meet your needs, our systems require a control architecture that is optimized and tailored to our processes. This enables maximum performance in terms of process safety, welding quality, reliability and operation, including traceability of your products.

Maximum performance for your applications

Our control systems have been designed specifically for Industry 4.0 in order to meet the increasing requirements of this field. By using a consistent concept of combining machine and STRUNK welding current controls, we enable uniform operation and usability of our technologies.

Our in-house power units from 50 Hz AC to 1000 Hz medium frequency DC to high frequency 30 kHz DC are used here. This combination offers a wide range of applications in the field of resistance welding technology. It ranges from micro welding applications (small part welding) to cable cross-sections in high-voltage electrical systems for EVs and connection cross-sections of copper materials in the field of power distribution beyond 300 mm².

Advantages of our welding current and machine controls

Our welding current and machine controls have interfaces to all relevant connection and bus systems. The most important performance features of our welding current controls include:

- complete sequencing capability for production of your specific cable sets,

- sophisticated monitoring strategies for quality control,

- internal databases for inline recording of welding results (quality control) and

- interfaces for communication with our machines and STRUNK MES for full traceability of your products and manufacturing steps.

We develop and build our welding current controls and cable components in-house. This enables us to respond to your individual requirements at any time.

power sources

optimum power density for every application

Resistance welding of non-ferrous metals requires high-quality power sources. We cover all areas of application with frequencies from 50 Hz AC to 30 Hz DC.

high-quality power sources for perfect welding results

Our areas of application range from cable connections, stranded wire terminal connections in the automotive wiring system, safety paths, e. g. for airbags and braking systems, autonomous driving, signal processing and power distribution for e-mobility to battery connectors and electronics. All applications are based on non-ferrous metals, mostly copper.

The desired high thermal and electrical conductivity places high demands on the welding process. In consequence, these also apply to our power sources, control systems and mechanics. For this reason, we have specialized in joining non-ferrous metals for 50 years and have optimized the power sources and control systems from parameterization to a very high conductor density.

Standard functions such as electrode management, control algorithms and monitoring functions form the basis for a stable and reproducible process. Modern power sources that supply 50 Hz AC in all power classes enable applications like hot crimping, welding under braze or applications with high connection cross-sections.

Performance features of our power sources

We integrate power sources with the following performance characteristics:

- 1000 Hz medium frequency for difficult material combinations with up to 100 kA at the electrodes, for applicationsranging from micro welding applications to challenging welding applications (possibly under braze), e.g. for temperature-sensitive components with adjacent overmolding with tightness requirements and

- 30 000 Hz high frequency for particularly small parts in micro welding with a focus on a DC welding current with virtually no residual ripple.

All power sources are adjusted to the specific application before they are integrated into our systems. Fast and precise control mechanisms in combination with high-performance power density and high duty cycle guarantee maximum process reliability for all variants. With our power sources, you benefit from excellent welding quality with maximum ease of use.

Switch cabinet construction for our systems

we implement the control center for your production

Switch cabinets form the heart of automated production systems. Therefore, we plan and manufacture them in-house.

Switch cabinets individually optimized for your application

The control cabinet for our customized systems is always planned and built according to your requirements. It is usually divided into power and signal distribution and contains a cooling unit. We therefore plan, design and implement all important functions of the systems according to your requirements.

Attention: We do not offer switch cabinet construction as a separate service. Instead, these units are part of our single-source solutions for your specific application.