Cable welding

high-quality non-ferrous metal connections with maximum service life and durabilityWelding cables made from copper or alloys, bare or coated

Feed-through connectors and end connectors can be created using splicing (cable welding). Resistance welding technology makes it possible to reliably connect coated or uncoated cables made of copper or alloys. Suitable equipment for every range currently makes it possible to manufacture cable connections with a cross-section of 0.1 to 400 mm².

For large quantities, a system with a tool adapted to the application and the individual workpiece is recommended. For constantly changing configurations (sequences) with different cross-sections, on the other hand, our automatic welding heads with different cross-positions are the optimum solution. The latter enable any cable configuration to be mapped as a node within a range. This concept can be implemented thanks to our sequence-capable control system, which is able to hande customer-specific cable sets.

Our systems impress with their extreme rigidity and high speed. With our in-house drives, we ensure optimum repositioning behavior for reliable and repeatable welding results. They are achieved with the shortest possible welding currents and high forces. The heat input is also low due to the short welding times.

Reliability and flexibility are essential for cable connections in motor vehicles. Perfect electrical conductivity must be guaranteed, as must the long-term durability of the connections.

Machines

(customer-specific solutions as an example)

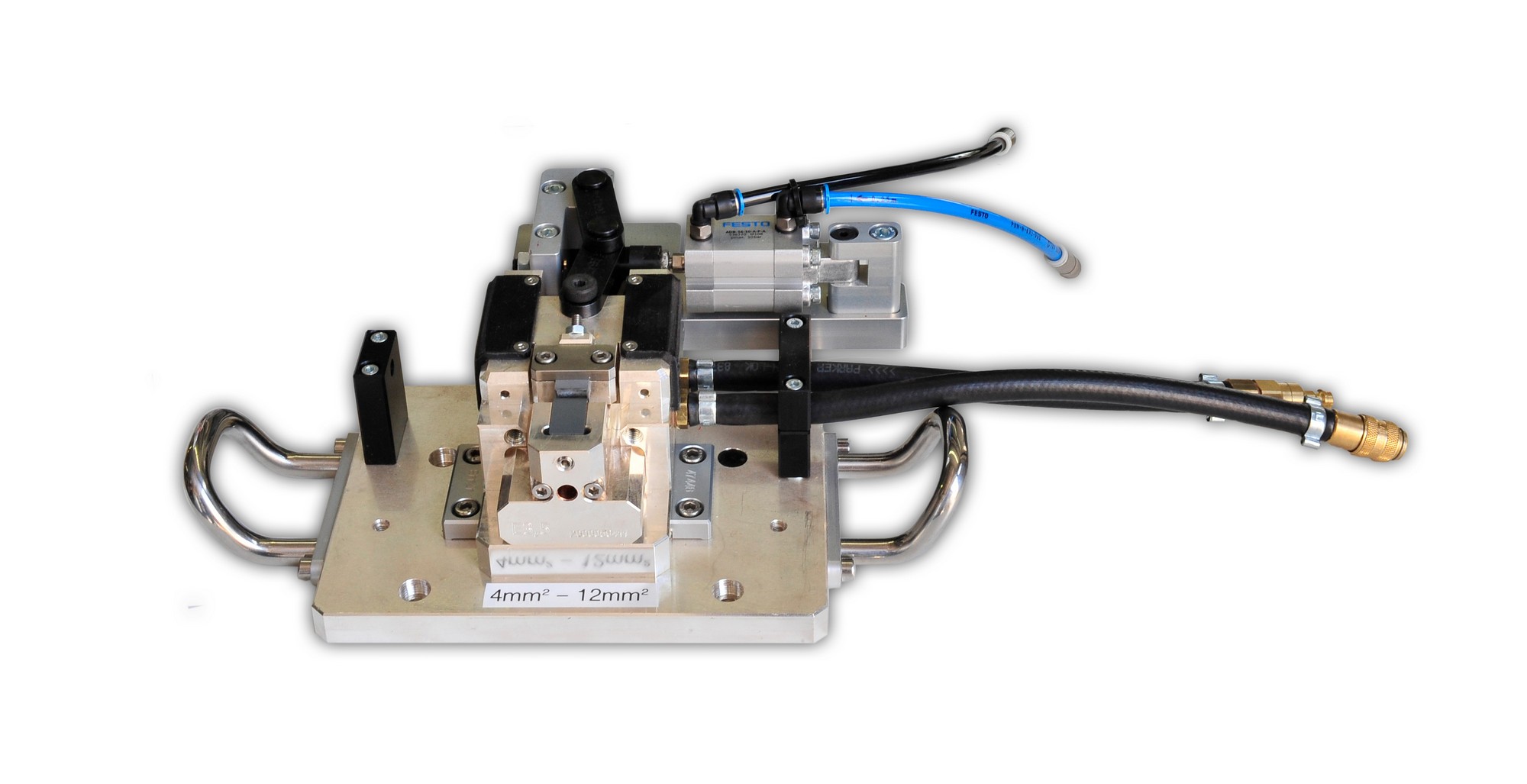

S-MMD1 for welding strands and end connectors

This S-MMD1 machine is designed for welding stranded wires into splices and/or end connectors in customer-specific dimensions. Strands are fed in from the front or from the right or left side of the welding tool. The system is equipped with a quick tool change system and can process twisted pairs. It also features a highly dynamic STRUNK drive, which allows for high-speed repositioning. Special guides ensure that force is applied centrally in the welding area in order to deliver high quality and reproducible results at all times. Welding tools with locking are used for achieving the most precise dimensions after welding.

We use the M4Ts board-based controller or the MCD PC/2 PC-based controller for welding current control.

Further infomation on these two kinds of welding current controls can be found in the corresponding brochures.

S-MMD2 for welding and compacting stranded wires

This S-MMD2 machine is designed for welding strands into splices and compacting tin-plated strands. For this purpose, it is set up as a manual welding station with tool-changing system on quick-change plates. This system can be converted to a different application (incl. terminal welding) within the machine’s performance range in nearly no time.

Welding tools with locking are used for achieving the most precise dimensions after welding.

WWS1 sequence welding machine for splicing and compacting

The WWS1 welding machine shown here is designed for the sequential production of end and feed-through joints of tin-plated and/or bare copper strands. Using the special tool, the electrodes can be continuously adjusted to the desired width using a motor. This means that the entire cross-section range can be covered without changing electrodes.Therefore, our WWS1 welding machine is ideal for the production of short series or for varying cable cross-sections.

In this table-top version, the machine components such as the switch cabinet, control unit, power unit, cooler and all pneumatic and electronic units are easily accessible and easy to maintain.

We develop and manufacture customized welding machines according to your individual requirements. Each machine can be equipped with a tool for the desired application and thus adapted to your individual process requirements.

Technical specifications

| Application range: | 0,50 mm – 20 mm² (depending on strand type and desired strand combination) |

| Feeding: | manually, from the left or right side of the welding tool |

| Welding Control: | MCD PC/2 |

Y-LB welding system for splicing and compacting

This Y-LB welding system is suitable for end connectors (compacting cable ends) or feed-through connectors (welding of cable connections) in the micro range. Its resistance welding technology can be used to weld copper strands as well as coated strands.

The welding tool is adapted to your respective application. It is fed manually from the left or right side. If the cross-section needs to be changed, the upper electrode must be replaced. All electrodes are located in quick-change pockets to avoid time-consuming set-up or adjustment work. The welding width is limited by insulators, enabling joint welding without protruding strands.

We develop and manufacture customized welding machines according to your individual requirements. Each machine can be equipped with a tool for the desired application and thus adapted to your individual process requirements.

Technical specifications

| Application range: | 0.35 mm – 2.5 mm² (depending on strand type and desired strand combination) |

| Machine type: | as a module, table-top device or table integration with built-in components (switch cabinet, controls, power unit, cooler, pneumatic and electronic parts) |

| Feeding: | manually, from the left or right side of the welding tool |

| Welding Control: | M4Ts or MCD PC/2 |

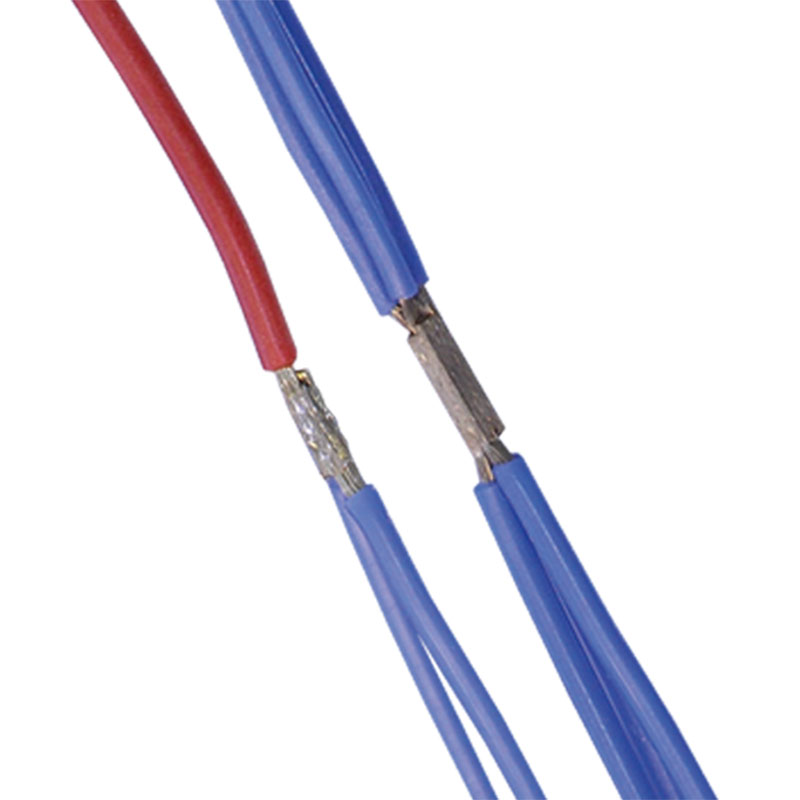

Samples

Resistance-welded stranded wire connections can be used not only in the low-voltage electrical system of an EV, but also in the high-voltage areas. This is because our systems are also ideal for producing connections with cross-sections of well over 300 mm². In addition to cables to energy storage systems (batteries) or traction distributors, connections to fuel cells can also be safely welded. High holding forces and definable dimensions facilitate the subsequent installation and routing of the cables.

Cable connections (splices), copper to copper or copper to tin-plated materials

Anwendung von Profillackdrähten zu Kabelschuh, versilbert als Handarbeitsplatz. Das Portalsystem ermöglicht durch den freien Werkzeugzugang die Verarbeitung von sehr kurzen Leitungs-/Abgriffslängen. Die Werkzeuge für unterschiedliche Anwendungen sind schnellwechselbar. Poka Yoke wird über überwachte Ablagen und unsere Werkzeugverwaltung “STRUNK Tool Mangement” realisiert.

HV splice 120mm²

Our low-cost STRUNK Y-LB module can be used for splicing (welding connections for cables) as well as compacting and welding cables onto connection shields.